You must be signed in to read the rest of this article.

Registration on CDEWorld is free. Sign up today!

Forgot your password? Click Here!

Since the introduction of cone beam computed tomography (CBCT) to the dental industry, most implant procedures are carefully preplanned to ensure sufficient bone volume and prosthetic restorability.1 This is true for single tooth replacement, partial edentulism, and whole-mouth reconstructions.

In single-tooth and quadrant treatment plans, clinicians and technicians can use the remaining healthy dentition as a guideline to virtually design a new implant-supported restoration for the edentulous spaces. Conventional or digital impressions are made and can be married to the CBCT, allowing laboratory prosthetic designs to be aligned with virtually planned implants. The prosthetic designs show the ideal tooth position in relation to adjacent and opposing dentition. Implant placement is then executed from this prosthetically driven workflow.

The edentulous patient requires a different workflow to accomplish the goal of prosthetically driven treatment. This is often referred to as a "dual CBCT scan" workflow, in which the patient wears a removable prosthetic device that has a fiducial registration during the CBCT. There is a second CBCT scan taken of just the prosthetic device with the fiducial registration. Those points of comparison allow for the marriage of the two separate CBCT scans together, and ultimately a virtual implant plan can be developed according to the prosthetic tooth position in the removable prosthesis.

For the full-arch patient with terminal dentition who will undergo immediate full-arch reconstruction, a popular approach is to use a system of "stackable" parts that fit on a bone fixation guide.2,3 This allows for static guidance of dental implants and also the connection of a prefabricated provisional prosthesis immediately following implant placement. These stackable systems have been very successful for the treatment of the full arch because the implant placement is made according to the preplanned prosthetic tooth position. Therefore, the laboratories know they will have sufficient prosthetic space to design and fabricate a definitive prosthesis that is not compromised due to lack of planning or space.

The stackable systems are not without flaws, however. Many think these are complicated due to the number of pieces involved and that they are also costly systems. So, an alternative treatment workflow was developed to reduce the number of components to a single conversion prosthesis. The complexity of this conversion prosthesis would be dependent on the availability of dynamic navigation for implant placement.4,5

This article will show two different patient examples of immediate full-arch reconstructions, one of which uses dynamic navigation for implant placement and the other that uses the conversion prosthesis itself as a static surgical template. The author chose specific software programs for their integration with each other and some unique capabilities, but other manufacturers offering software for design, implant planning, and guided surgery include (but are not limited to) 3Shape, Blue Sky Bio, Carestream Dental, Dentsply Sirona, exocad, and Kulzer.

Patient Treatment with Dynamic

Navigation

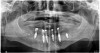

This prosthetically driven workflow can be completed in two patient appointments. Following acceptance of the treatment plan, the process begins with a digital denture design. Either conventional or digital impressions and jaw relation records are made. Any conventional records are sent to the laboratory to fabricate models for scanning. At the first appointment, there is also a comprehensive esthetic evaluation (Figure 1) that will assist in determining the desired tooth position for the future prosthesis. This includes determining the appropriate midline, incisal edge position, lip support, plane of occlusion, vertical dimension, and tooth and gingiva colors. Lastly, a CT scan of the patient is acquired (Figure 2).

Using the clinician's notes from the esthetics evaluation as well as photographs, the digital denture design is made in the design software (AvaDent Connect; Global Dental Science LLC) (Figure 3). Following the approval of the denture design, two specific conversion prosthesis tools are added to the design.6 The first is a positioning handle, which is used to hold the denture from outside the mouth during the conversion process. The second is the patented occlusal locks, which provide a temporary static occlusion to ensure the occlusal scheme designed in the software is maintained during the conversion process. With these additions, the STL file of the conversion denture is imported to the implant planning program (DTX Studio Implant; Nobel Biocare). It is imported to the appropriate coordinate system in relation to the CT data so the virtual implant planning can be made knowing the approved digital denture position (Figure 4). The implant position is then exported from the implant planning program back to the design software so that precise holes can be opened in the appropriate places in the conversion denture. The implant plan is also imported into the dynamic navigation software (XGuide; X-Nav Technologies) (Figure 5). The monolithic conversion denture is milled for strength and durability (Figure 6 and Figure 7).

The second patient appointment includes any planned extractions and the surgical placement of implants using dynamic navigation that follows the virtual implant plan (Figure 8). After the implants are placed, any planned alveoloplasty is made using the implant shoulders as the guide for the reduction. Bone mill guides can be installed to protect the implant connection during the reduction. Any planned transmucosal abutments are connected. Temporary copings are also connected (Figure 9). The conversion denture is tried in to confirm that copings are positioned in the premilled openings in the conversion denture (Figure 10 and Figure 11). Using the occlusal locks and positioning handle, the temporary copings are picked up while the patient is set into static occlusion using autopolymerizing resin. After the resin is cured, the conversion denture is unscrewed from the patient and refined chairside. The soft tissue flaps are sutured, and the finished, polished conversion prosthesis is delivered (Figure 12 and Figure 13).

Patient Treatment with Static Guidance

This workflow is also completed in two patient appointments. The same records and esthetic evaluation that was done in the dynamic navigation workflow are also completed for the static guide process (Figure 14 and Figure 15). A digital denture design is made (Figure 16), and once approved, the patented occlusal locks are added. No positioning handle is needed for this specific conversion denture/static guide (SurgiDenture; Global Dental Science, LLC), as the denture will be anchored to the patient with stabilizing pins. The virtual implant planning is made in relation to the digital denture design (Figure 17). The implant coordinates are exported from the planning program in relation to the denture design so that specific guidance holes can be programmed and ultimately milled into the denture (Figure 18 and Figure 19). These holes are compatible with a guided surgery drilling system (NobelGuide; Nobel Biocare).7,8

At the second patient appointment, any extractions are made and the monolithic denture is seated and anchored to the patient (Figure 20 and Figure 21). The implant osteotomy sites are prepared just as they would be in the original guided surgery protocol using the stainless-steel inserts. After all implants are placed to depth, the abutments and copings are connected and cured to the denture with autopolymerizing resin prior to removal of the denture from the patient (Figure 23). With the denture anchored to the bone and the occlusal locks in place, the digitally designed occlusal scheme is maintained. Following the pick-up of the copings, the denture is removed from the patient. Any required alveoloplasty is performed to the level of the implant shoulder. The denture is refined and converted into the screw-retained provisional in a similar fashion to the navigated example described above (Figure 24). The occlusal locks and anchor pin supports are removed as part of the finishing process (Figure 25 and Figure 26).

Discussion

The treatment workflows described above require only a single prosthetic piece for the immediate full-arch reconstruction with dental implants. This is a simplification and reduction in overhead compared to the various stackable systems available in the dental marketplace today.

The major change in treatment sequence is that the implants are placed before the alveoloplasty and the implant shoulders themselves become the "guide" for the bone reduction. Damaging the implant connection during the alveoloplasty is avoided by the use of implant-specific bone mill guides and calibrated trephines (Figure 22). This allows for the safe removal of bone adjacent to the implant.

In the static guide method, there is a 28-mm limitation on the depth that the apex of the planned implant can be from the collar of the denture. This is due to the surgical instrumentation and guided implant mounts. In the dynamically navigated method, there is no limitation on depth.

In the static guide method, an additional hole is required in the denture for the prosthetic connection of sites using angulated abutments (like the all-on-4 treatment concept). There is no implant direction hole needed for the dynamically navigated method because the denture itself is not used to place the implants. Only the prosthetic access holes are needed in the conversion denture for that workflow.

Utilizing the technology to mill a monolithic denture where the denture teeth and denture base are all one union increases the strength and durability of the conversion prosthesis. Opening multiple access holes in the denture does not affect the integrity of the prosthesis and there is no concern of an individual denture tooth breaking out of the base.

The accuracy of these workflows is predicated on quality impressions at the first patient appointment. The fit of the conversion denture to the ridge is directly related to the conventional or digital impression made at the first treatment appointment. Additionally, the occlusal locks provide stability by way of a temporary static occlusion with the opposing dentition (Figure 7 and Figure 18). When seated properly, there is no question of the accurate position of the conversion denture for pick-up of the temporary copings.

It is the author's preference to pick up the temporary copings with the soft tissue flaps still open so that it is possible to clinically see that all hardware is fully seated on the implants or implant abutments. The design of the intaglio surface of the conversion prosthesis should dictate soft tissue healing. The swollen soft tissues should not dictate the design of the intaglio surface of the prosthesis. Therefore, in the author's experience, there is often compression of the conversion prosthesis on the soft tissue at the time of insertion. The gingiva then heals around the conversion prosthesis over the next several weeks. If radiographic confirmation is obtained of the conversion prosthesis fully seated at the day of surgery, then that prosthesis can also be used to capture the final impression 8 to 12 weeks later.9

Conclusion

Monolithic digital denture technology allows for the production of a single prosthetic device that simplifies the treatment of the immediate full-arch implant reconstruction. Aligning the denture design with virtual implant planning improves patient outcomes, making the final prosthetics more predictable. While this technology provides repeated expected results, there is still a premium placed on the clinician for the impressions, jaw relation record, and esthetic evaluation.

Acknowledgment

The author would like to thank Robert Pauley Jr., DMD, for the clinical photos of the dynamic navigation case and Glenn J. Wolfinger, DMD, for the clinical photos of the SurgiDenture case.

About the Author

Stephen F. Balshi, MBE

President

CM Prosthetics, Inc.

Fort Washington, PA

References

1. Jaju PP, Jaju SP. Clinical utility of dental cone-beam computed tomography current perspectives. Clinal, Cosmetic and Investigational Dentistry. 2014 Apr 2;6:29-43.

2. Pikos MA, Magyar CA, Llop DR. Guided full-arch immediate-function treatment modality for the edentulous and terminal dentition patient. Compend Contin Educ Dent. 2015;36(2):116,119-126,128.

3. Alzoubi F, Massoomi N, Nattestad A. Bone reduction to facilitate immediate implant placement and loading using CAD/CAM surgical guides for patients with terminal dentition. J Oral Implantol. 2016;42(5):406-410.

4. Emery RW, Merritt SA, Lank K, Gibbs JD. Accuracy of dynamic navigation for dental implant placement-model-based evaluation. J Oral Implantol. 2016;42(5):399-405.

5. Block MS, Emery RW, Cullum DR, Sheikh A. Implant placement is more accurate using dynamic navigation. J Oral Maxillofac Surg. 2017;75(7):1377-1386.

6. Balshi TJ, Wolfinger GJ, Balshi SF. Positioning handle and occlusal locks for the Teeth-in-a-Day protocol. J Prosthet Dent. 2016;115(3):274-277.

7. Parel SM, Triplett RG. Interactive imaging for implant planning, placement, and prosthesis construction. J Oral Maxillofac Surg. 2004;9:41-47.

8. Balshi SF, Wolfinger GJ, Balshi TJ. Surgical planning and prosthesis construction using computed tomography, CAD/CAM technology, and the internet for immediate loading of dental implants. J Esthet Restor Dent. 2006;18:312-325.

9. Balshi TJ, Wolfinger GJ, Alfano SG, et al. fabricating an accurate implant master cast: a technique report. J Prosthodont. 2015;24:654-660.